Comprehensive Solution of Refractories

Other Products

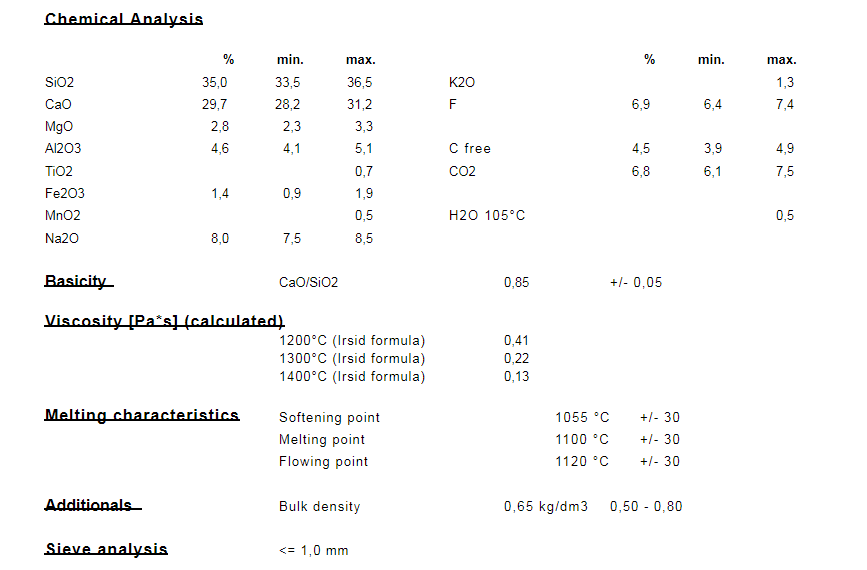

We could design and produce the Mold powder as per the steel types the customers producing.

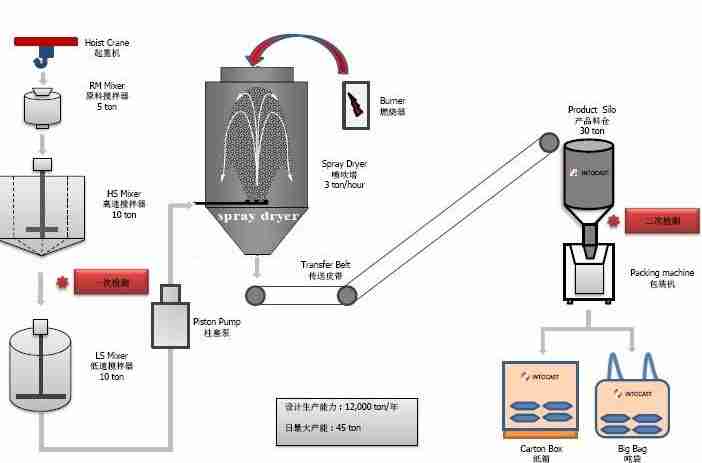

Mold powder production process

Get a free update quote

Stay informed and receive company the latest product information, the latest product offers and price fluctuations, and notices about future events.

The role of mold Powder

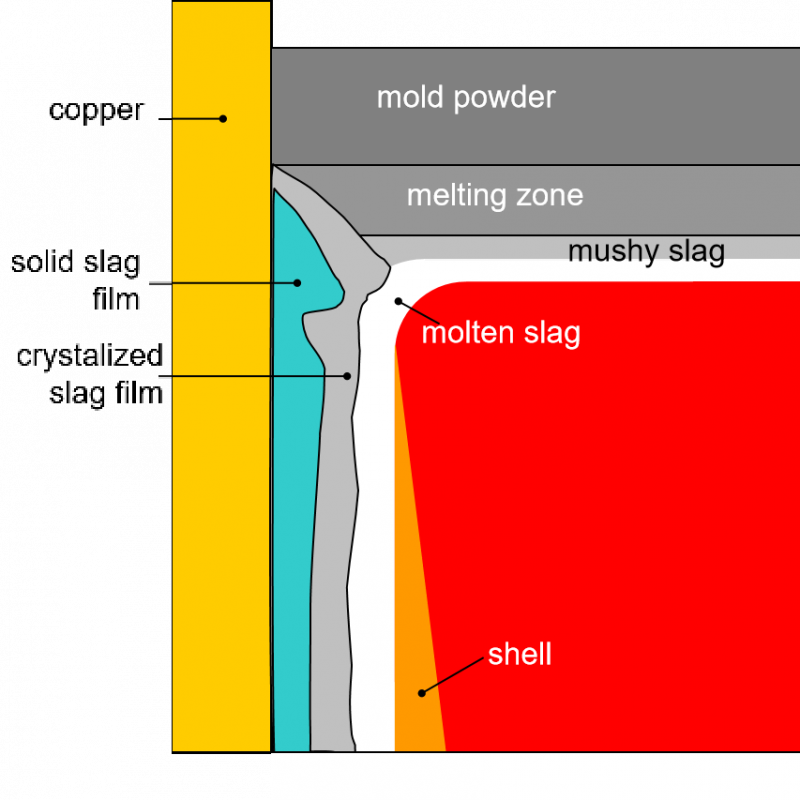

1. Provides lubrication for cast billets

The lubrication referred to here refers to the liquid lubrication of the slag film between the billet shell and the crystallizer wall in the crystallizer.

The lubrication of the protective slag is one of the most important properties of the slag, especially at high drawing speeds.

The only way to improve the lubrication in the crystallizer is to expand the liquid phase area of the slag film and to improve the performance of the liquid phase slag film.

The current research on the lubricating properties of slag protection has two aspects, one is to improve the performance of slag protection so that it has good lubrication; the second is to improve the crystallizer vibration form to improve its lubrication effect.

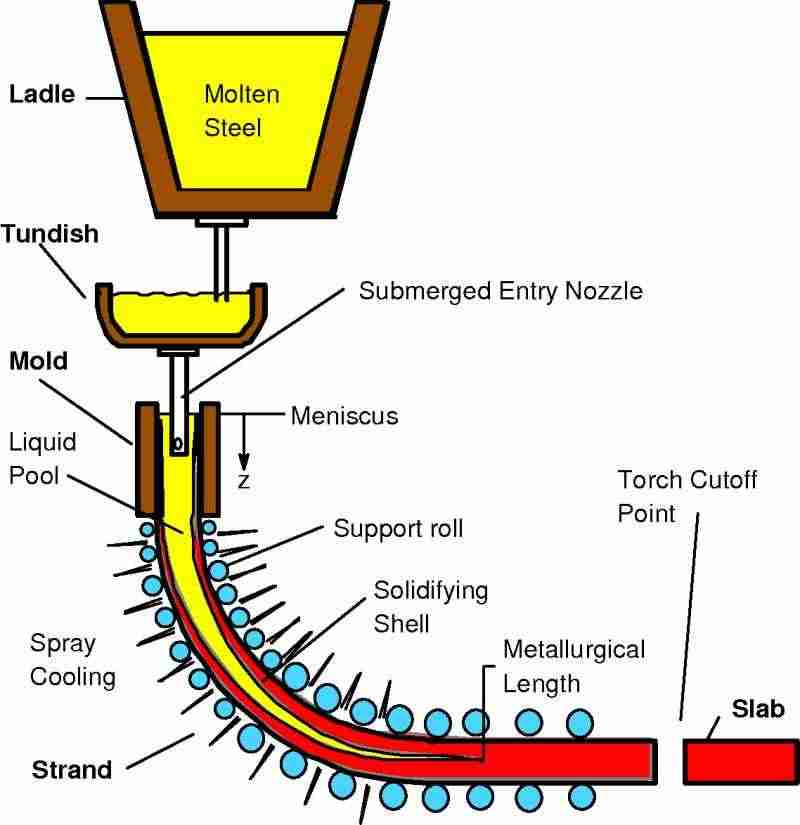

2. Adiabatic insulation

Protective slag in the crystallizer on the steel surface of the adiabatic insulation role, mainly by the protection of slag powder slag layer thickness and powder slag layer of physical properties to achieve (powder slag layer thickness, weight, and carbon content).

Mainly to prevent crusting of the steel surface in the crystallizer and low temperature at the bending moon surface, resulting in billet surface and subcutaneous inclusions.

According to the needs of the steel, choose to protect the slag insulation performance, such as casting high alumina steel, 1Crl8NiTi, and other steel, to choose a good insulation performance of the slag system, pay special attention to the bending moon surface at the insulation, otherwise, will cause the casting billet surface and a large number of subcutaneous inclusions.

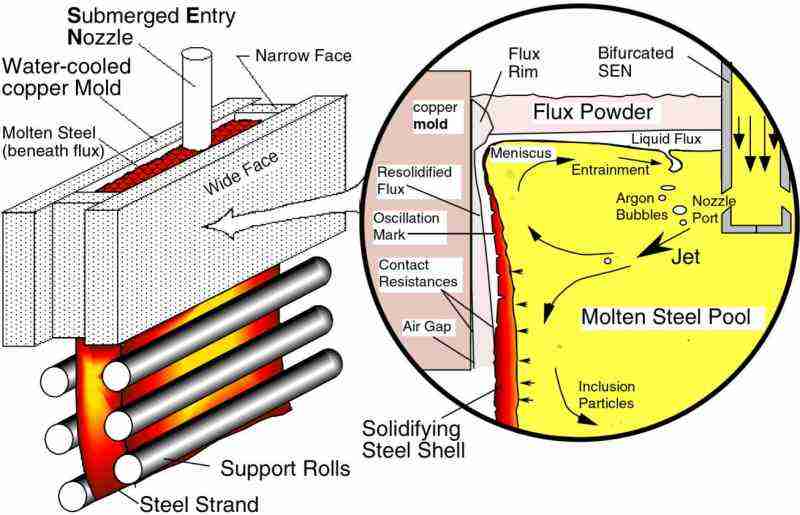

3. Absorption of uplifting inclusions in the steel

Protective slag should have the ability to absorb the inclusions in the steel liquid, especially the inclusions in the crystallization at the curved moon surface. The protective slag should be assimilated on time. Otherwise, it will cause a large number of inclusions on the surface of the cast billet and under the skin.

At present to make the protection slag has the ability to absorb inclusions is not difficult, but difficult in the protection slag after absorbing a large number of inclusions, but also to maintain its good performance to meet the requirements of the continuous casting process, especially lubrication performance and uniform heat transfer performance.

Usually high inclusions in steel grades, such as those containing aluminum, titanium, and rare earth elements, the oxides of these elements into the slag, so that the performance of the protective slag has a large change, such as the alkalinity of the protective slag, melting temperature, and viscosity of a large change. When solving this type of steel, often choose a high alkaline high vitrification of the protection slag, received good results.

Basic properties of mold Powder

Main indicators

Alkalinity

Viscosity

Melting temperature

Melting speed

Crystallisation temperature

Particle size

moisture content

Bulk density

JOIN PARTNER NETWORK

If you want to get the latest refractory advice and quality quotes please leave your email